There are many benefits to the food or supplement manufacturer that can be achieved through encapsulation.

- Reduce Overages: To ensure label claim is met, often higher levels or “overages” must be added to compensate for expected losses in nutrient potency that occur during processing. Given the high costs of many vitamins, these overages can eat into your profit margins over time. Encapsulation protects these nutrients, reducing losses and minimizing overages. The result is significant cost savings.

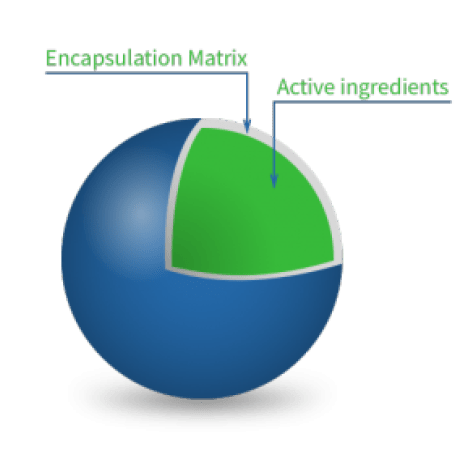

- Protection: From moisture, acids, ingredient interactions, heat, and exposure to oxygen.

- Release Parameters: Engineered so that the nutrient is released when desired, for instance at a specified temperature or in the stomach for digestion.

- Flavor and Odor Masking: Increase consumer acceptance by minimizing unpleasant tastes and odors associated with certain nutrients.

- Ease of Handling: Encapsulated ingredients are dry and free-flowing.

- Precision: The stability afforded by encapsulated ingredients allows measuring and delivery of precise levels of the desired nutrient.

- Effectiveness: Encapsulation is critical to such products as medical foods, nutraceuticals, and meal-replacement products where characteristics such as stability, bioavailability, delivery, and effectiveness are closely regulated.